- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

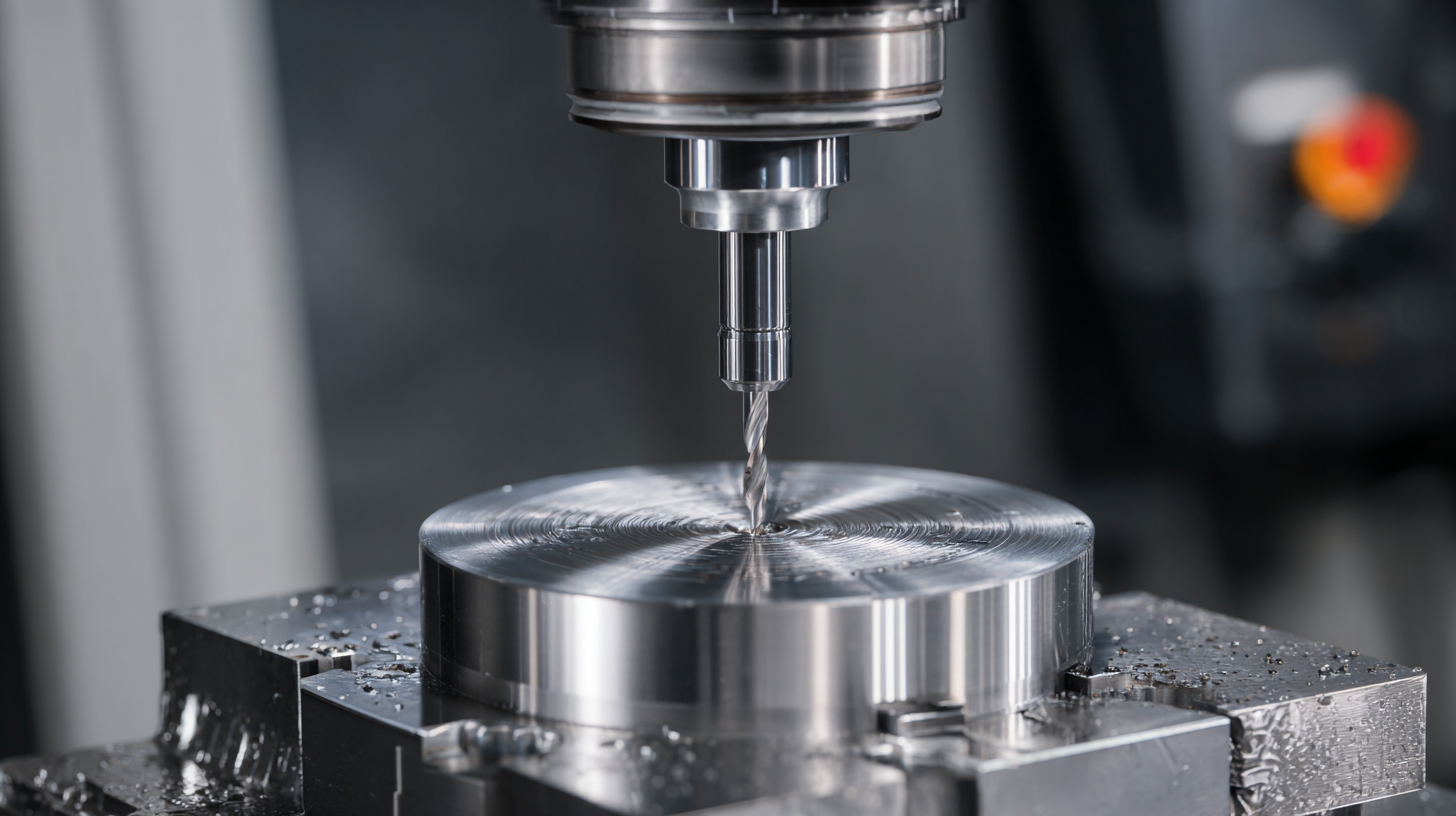

Top Strategies for Sourcing the Best High Precision Machining Solutions Worldwide

In today's rapidly evolving manufacturing landscape, high precision machining has emerged as a critical component in achieving superior product quality and performance. According to a report by IBISWorld, the global precision machining industry is projected to grow at a CAGR of 5.2% over the next five years, driven by rising demand across various sectors, including aerospace, automotive, and medical devices. As companies seek to enhance operational efficiency and reduce production costs, sourcing high precision machining solutions from reputable suppliers worldwide has become imperative. This blog will explore the top strategies for identifying and partnering with the best service providers in the high precision machining sector, ensuring that businesses can maintain a competitive edge in an ever-increasingly global market.

Identifying Key Industry Standards for High Precision Machining Solutions

In the realm of high precision machining solutions, adherence to key industry standards is crucial for ensuring product quality and operational efficiency. The global demand for high precision machining has been steadily rising, evidenced by the CNC machine market, projected to grow from $101.22 billion in 2025 to approximately $195.59 billion by 2032, reflecting a compound annual growth rate (CAGR) of 9.9%. This significant growth highlights the increasing need for manufacturers to integrate advanced technologies and adhere to standardized practices that align with industry benchmarks.

Furthermore, the introduction of the “National Intelligent Manufacturing Standards System Construction Guidelines (2024 Edition)” by the Ministry of Industry and Information Technology and the Standardization Administration of China underscores the importance of a well-structured approach to standardization in the smart manufacturing sector. Establishing such frameworks not only promotes high-quality development but also enhances global competitiveness. The forecasted expansion of the cutting tool market, projected to reach $9.8 billion by 2032 with a CAGR of 4.26%, further illustrates the urgency for companies to prioritize compliance with these evolving standards to meet market demands effectively.

Evaluating Supplier Capabilities and Experience in Precision Machining

When sourcing high precision machining solutions, evaluating supplier capabilities and experience is paramount. According to a report by Grand View Research, the global precision machining market is expected to reach $136.5 billion by 2027, growing at a compound annual growth rate (CAGR) of 6.5%. This explosive growth underscores the need for companies to partner with suppliers that not only have advanced machining technologies but also a proven track record in delivering quality components.

A critical aspect of assessing suppliers is their experience in the specific materials and processes relevant to your industry. For instance, aerospace and medical device sectors require machining solutions that adhere to stringent tolerances and regulatory standards. A survey by Deloitte highlighted that 33% of manufacturers reported difficulties in finding suppliers that meet their high standards for precision and reliability. Thus, it's essential to vet potential suppliers thoroughly, examining case studies and client testimonials to ensure they possess the expertise necessary to meet the unique demands of high precision machining projects.

Leveraging Advanced Technology for Enhanced Machining Quality

In today's competitive landscape, leveraging advanced technology is essential for achieving enhanced machining quality. The introduction of automated systems, such as CNC (Computer Numerical Control) machines, has revolutionized the precision machining industry. These advanced tools not only reduce human error but also increase production efficiency, making it possible to achieve tighter tolerances and improved finishes. By incorporating real-time monitoring and data analytics, manufacturers can fine-tune their processes, leading to greater consistency and quality in the machined parts.

Furthermore, advanced technologies like additive manufacturing and laser cutting are gaining traction for high precision machining solutions. These methods allow for intricate designs and innovations that were once thought impossible. Embracing such technologies can help businesses stay ahead of the curve by offering custom solutions tailored to specific client needs while maintaining the highest quality standards. The integration of IoT (Internet of Things) in machine operations also leads to smarter workflows, enabling predictive maintenance and minimizing downtime, thereby solidifying a company's reputation for excellence in high precision machining.

Implementing Effective Communication Strategies with Global Suppliers

Effective communication is the cornerstone of establishing strong relationships with global suppliers in high precision machining. To navigate the complexities of cross-border collaboration, businesses must prioritize clarity and consistency in their interactions. Utilizing multiple communication platforms—such as video conferencing, instant messaging, and email—ensures that all parties are on the same page. Regular updates on project timelines, specifications, and expectations can prevent misunderstandings and enhance overall efficiency.

Effective communication is the cornerstone of establishing strong relationships with global suppliers in high precision machining. To navigate the complexities of cross-border collaboration, businesses must prioritize clarity and consistency in their interactions. Utilizing multiple communication platforms—such as video conferencing, instant messaging, and email—ensures that all parties are on the same page. Regular updates on project timelines, specifications, and expectations can prevent misunderstandings and enhance overall efficiency.

Additionally, understanding cultural differences plays a crucial role in successful communication. Companies should invest time in learning about their suppliers’ communication styles and business practices. This not only fosters mutual respect but also reduces friction in negotiations and day-to-day interactions. Also, providing detailed documentation, including technical drawings and quality standards, can bridge gaps caused by language barriers. Emphasizing transparency and open dialogue helps build trust, enabling both parties to work collaboratively towards achieving high-precision machining solutions that meet or exceed expectations.

Best Practices for Cost Management in Sourcing Precision Machining Services

When sourcing precision machining services, effective cost management is crucial to ensure high-quality outputs without overextending your budget. One of the best practices is to establish clear specifications right from the start. By defining the required tolerances, materials, and delivery timelines, you not only refine the selection process but also minimize the risk of costly revisions or rework later on. Leveraging technology for detailed design and prototyping can further enhance clarity and reduce misunderstandings during the sourcing phase.

Additionally, fostering strong relationships with suppliers is key to negotiating better terms and pricing. Engaging in open communication about your project requirements and potential constraints allows for collaborative problem-solving, which can lead to innovative solutions and improved pricing structures. Consider diversifying your supplier base to avoid dependency on a single source, as this can empower you to compare quotes more effectively and select the best value without compromising on quality. By focusing on these cost management strategies, businesses can achieve substantial savings while sourcing top-notch precision machining solutions globally.

Top Strategies for Sourcing the Best High Precision Machining Solutions Worldwide

| Dimension | Best Practices | Cost Management Tips | Regional Considerations |

|---|---|---|---|

| Supplier Selection | Evaluate suppliers based on quality certifications | Negotiate bulk pricing agreements | Consider regional labor costs |

| Technical Capability | Assess advanced machining technologies | Utilize process efficiency audits | Adapt to local technological advancements |

| Logistics | Optimize shipping schedules | Implement Just-In-Time (JIT) inventory | Analyze regional shipping routes |

| Quality Control | Establish stringent QC protocols | Invest in automated quality inspection systems | Understand local regulatory standards |

| Innovation | Collaborate on R&D with suppliers | Focus on long-term value over short-term savings | Leverage regional innovations |