- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

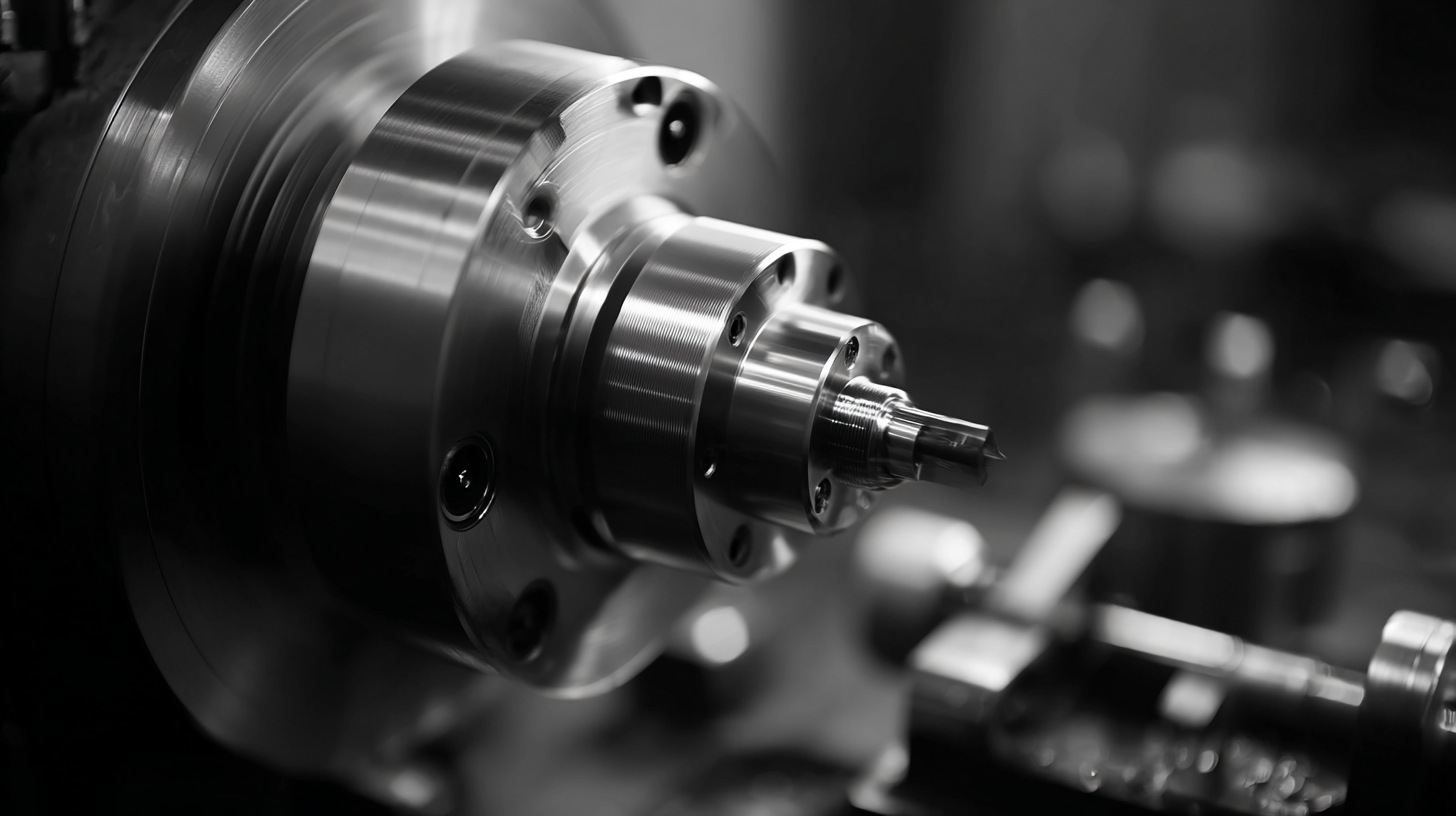

Ultimate Comparison of Top Providers for Best CNC Precision Machining

In today's competitive manufacturing landscape, the demand for high-quality components has surged, placing CNC precision machining at the forefront of industrial innovation. According to a recent report by MarketsandMarkets, the CNC machining market is expected to reach USD 100 billion by 2025, growing at a CAGR of 6.5%. This shift emphasizes the necessity for businesses to choose the right manufacturer capable of delivering precision-engineered solutions. With numerous providers claiming expertise in this field, identifying a reliable sculptor of intricate designs and tight tolerances is crucial. Factors such as advanced technology, material proficiency, and stringent quality control processes come into play when evaluating potential partners. This article will serve as a guide to help you navigate these considerations and make an informed decision in selecting a premier CNC precision machining manufacturer that aligns with your operational needs and quality standards.

Challenges in CNC Precision Machining: An Overview of Industry Standards

In the realm of CNC precision machining, the industry faces numerous challenges that are integral to maintaining high standards and delivering quality results. With the increasing demand for high-precision components across various sectors, including medical and aerospace, manufacturers are forced to adapt to rigorous industry norms. This has led to the emergence of advanced machining technologies that enhance productivity and precision. For instance, the adoption of digital readout systems significantly improves manufacturing efficiency, ensuring that the machines operate within defined tolerances and that the output meets stringent specifications.

Common Issues Faced by Manufacturers in CNC Technologies

The adoption of new digital manufacturing technologies has revolutionized CNC precision machining, but manufacturers still face significant challenges in this evolving landscape. Common issues include parts shortages, workforce difficulties, and the need for advanced skills to operate complex CNC equipment. According to a recent report, companies in the aerospace supply chain are increasingly struggling to address these parts shortages, which were exacerbated by global disruptions and a skilled labor gap, leading to delays and increased production costs.

Artificial intelligence (AI) and machine learning (ML) have emerged as crucial tools to address these manufacturing hurdles. A review highlighted that AI applications can enhance operational efficiency by streamlining processes and predictive maintenance, ultimately improving decision-making in CNC machining operations. However, the integration of AI in manufacturing poses its own set of challenges, such as the need for substantial investments and training, which many manufacturers are still navigating. As the industry evolves, embracing these digital innovations alongside addressing workforce skill gaps will be essential for maintaining competitiveness in the market.

Ultimate Comparison of Common Issues Faced by Manufacturers in CNC Technologies

This chart represents the percentage of common issues faced by manufacturers in CNC precision machining technologies, showcasing the challenges that impact efficiency and production quality.

Comparative Analysis of Leading CNC Machining Providers' Solutions

In the ever-evolving landscape of CNC precision machining, it is crucial to conduct a comparative analysis of leading providers to determine which can deliver the best solutions tailored to industry demands. With a projected market size of $144.85 billion by 2032, the machine tools sector is experiencing significant growth driven by advancements in technology and increasing automation needs. Providers are distinguished not only by their technological prowess but also by their ability to offer customized options that cater to specific industry requirements.

Amidst this competitive environment, various players are leveraging innovative approaches, such as the integration of smart technology and IoT capabilities, making their offerings more appealing to manufacturers seeking efficiency and precision. Companies that can effectively demonstrate their expertise in CNC machining while also highlighting their adaptability and customer-focused solutions will emerge as leaders. Ultimately, this comparative landscape will guide businesses in selecting the most suitable machining partner as they navigate through an increasingly complex market.

Evaluating the Impact of CNC Machining Problems on Production Efficiency

CNC machining plays a critical role in the efficiency of production across various industries. A report by the National Institute of Standards and Technology indicates that production inefficiencies due to CNC machining problems can lead to an annual loss of around $21 billion in the manufacturing sector. Common issues, such as tool wear, misalignment, and software errors, can cause significant downtime and negatively impact output quality. With precision being paramount, a slight deviation in machining can result in costly reworks and delays, further exacerbating production challenges.

Moreover, according to a study published by the International Journal of Advanced Manufacturing Technology, 60% of manufacturers reported experiencing CNC-related issues that directly affected their efficiency. Implementing robust monitoring and maintenance protocols can mitigate these issues, enhancing overall productivity. For instance, predictive maintenance practices can reduce machine downtime by up to 30%, ensuring that CNC operations run smoothly and efficiently. As companies continue to invest in advanced technologies, addressing these problems will be crucial in maintaining competitive advantage in an increasingly demanding market.

Innovations to Address CNC Precision Machining Challenges in the Industry

In the realm of CNC precision machining, innovation is crucial to overcoming the persistent challenges faced by manufacturers. One major issue is the demand for higher accuracy and efficiency while minimizing waste. To address this, many leading providers are adopting advanced technologies such as artificial intelligence and machine learning to optimize machining processes. These innovations enable real-time monitoring of operations, facilitating immediate adjustments that enhance precision and reduce errors.

Moreover, the integration of IoT (Internet of Things) has transformed traditional machining environments into smart factories. By connecting machines and tools, manufacturers can collect data on various performance metrics, leading to insightful analytics that drive continuous improvement.

Companies are also investing in advanced materials and adaptive tooling systems designed to withstand the rigors of complex applications, ensuring durability while maintaining high precision. As these innovations reshape the landscape, the competition among top CNC providers intensifies, pushing the boundaries of what is possible in precision machining.