- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

Unlocking Precision: The Essential Guide to 5 Axis Milling Machines for Modern Manufacturing

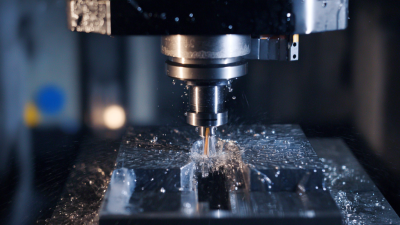

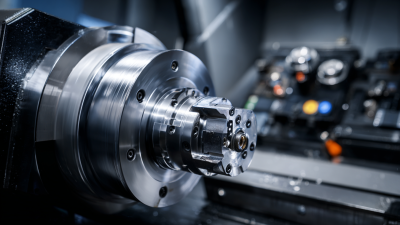

In the rapidly evolving landscape of modern manufacturing, the importance of precision and efficiency cannot be overstated. The emergence of advanced technologies has revolutionized traditional machining processes, with the 5 axis milling machine standing at the forefront of this transformation. Unlike conventional milling machines, a 5 axis milling machine can manipulate tools along five different axes simultaneously, allowing for unparalleled precision and the ability to produce complex geometries that were once thought impossible. This capability not only enhances the quality of finished products but also streamlines workflows, reduces lead times, and minimizes material waste. As industries continue to demand higher standards, understanding the intricacies and advantages of 5 axis milling machines becomes essential for manufacturers seeking to remain competitive in today’s market.

This guide aims to unlock the potential of these sophisticated machines, provide insights into their operational benefits, and explore their applications in modern manufacturing settings.

Choosing the Right 5 Axis Milling Machine for Your Manufacturing Needs

Choosing the right 5-axis milling machine for your manufacturing needs involves a careful consideration of various factors that can significantly impact production efficiency and product quality. First, assess the complexity of the parts you intend to manufacture. If your work involves intricate shapes and tight tolerances, a high-precision machine with advanced capabilities is a necessity. Look for features such as a rigid frame, high-speed spindles, and a versatile tool changing system to enhance productivity and reduce downtime.

Next, consider the size and scope of your operations. Smaller workshops might benefit from compact, multi-functional machines that can handle a variety of tasks without occupying too much floor space. In contrast, larger operations may require high-capacity machines that can accommodate larger workpieces and complex setups. Additionally, evaluating software compatibility and customization options is crucial, as modern 5-axis machines often come equipped with advanced CNC systems that can streamline programming and operational efficiency. By aligning your specific manufacturing requirements with the right machine specifications, you can significantly elevate your production capabilities in a competitive landscape.

Unlocking Precision: The Essential Guide to 5 Axis Milling Machines for Modern Manufacturing

| Feature | Details |

|---|---|

| Machine Type | Vertical 5 Axis Milling Machine |

| Work Material | Aluminum, Steel, Titanium, Composite |

| Spindle Power | 10-30 kW |

| Travel Range (X, Y, Z) | 1000 x 800 x 600 mm |

| Number of Axes | 5 |

| Maximum Workpiece Weight | 500 kg |

| Control System | CNC with ISO compatibility |

| Precision | 0.01 mm |

Key Features to Consider When Evaluating 5 Axis Milling Technology

In evaluating 5 axis milling technology for modern manufacturing, it is essential to consider key features that enhance operational efficiency and precision. One significant aspect is the integration of advanced machine learning algorithms, which can optimize the machining process through innovative segmentation methodologies. By utilizing multi-sensor measurements, manufacturers can better monitor and adjust the milling phases, improving accuracy and minimizing errors during production.

Furthermore, the market for CNC machines is evolving rapidly due to the increasing demand for precision manufacturing driven by industries such as oil, gas, and maritime. The advent of data model-based toolpath generation allows for customized milling strategies that cater to specific project requirements. This capability not only streamlines production processes but also significantly boosts the competitive edge in a landscape shaped by technological advancements. As manufacturers seek to adopt these innovations, understanding the critical features of 5 axis milling machines will be pivotal to achieving superior results in their operations.

Common Applications of 5 Axis Milling in Modern Industries

5-axis milling machines are revolutionizing modern manufacturing across various industries. Their ability to move simultaneously along multiple axes allows for more complex geometries and intricate designs. Common applications of 5-axis milling include aerospace components, automotive parts, and medical devices, where precision and efficiency are crucial. In aerospace, for instance, parts need to meet stringent safety standards while being lightweight, making 5-axis machining an ideal choice for achieving both goals. Similarly, in the automotive industry, these machines enable the production of complex engine blocks and transmission cases with tight tolerances.

Tip: When implementing 5-axis milling in your production line, consider investing in robust CAM (Computer-Aided Manufacturing) software, as it can significantly enhance machining accuracy and reduce setup times.

Moreover, 5-axis milling is also becoming increasingly popular in the production of custom medical devices. The ability to create tailored implants or prosthetics that fit precisely to individual patients is a game changer in healthcare. This technology not only improves patient outcomes but also fosters innovation in medical solutions.

Tip: To optimize the use of 5-axis milling, it’s essential to ensure your team is well-trained in operating these machines and familiar with best practices in tool selection and workholding techniques.

Maximizing Efficiency: Tips for Optimizing Your 5 Axis Milling Workflow

Maximizing efficiency in a 5 axis milling workflow is pivotal for modern manufacturing, allowing for complex geometries to be machined with unparalleled precision. One crucial tip for optimizing this process is to ensure proper fixturing. Securely holding the workpiece not only prevents movement during machining but also allows for faster setup times, reducing downtime. Utilizing adaptive fixturing systems can further enhance flexibility, enabling quick changes between different projects without significant manual adjustments.

Maximizing efficiency in a 5 axis milling workflow is pivotal for modern manufacturing, allowing for complex geometries to be machined with unparalleled precision. One crucial tip for optimizing this process is to ensure proper fixturing. Securely holding the workpiece not only prevents movement during machining but also allows for faster setup times, reducing downtime. Utilizing adaptive fixturing systems can further enhance flexibility, enabling quick changes between different projects without significant manual adjustments.

Another key area of focus should be toolpath optimization. By leveraging advanced CAM software, manufacturers can simulate and refine toolpaths to minimize machining time and tool wear. Implementing strategies such as high-speed machining techniques and appropriate feed rates can significantly cut down cycle times while maintaining high-quality outputs. Additionally, regularly analyzing and adjusting parameters based on real-time feedback from the machining process can lead to continuous improvement in efficiency, ensuring that the milling operation remains competitive in a rapidly evolving industry.

Future Trends in 5 Axis Milling: Innovations and Advancements to Watch

The landscape of 5 axis milling is rapidly evolving, driven by continuous innovations and advancements that are reshaping modern manufacturing. According to a report by MarketsandMarkets, the global 5-axis milling machine market is projected to grow at a CAGR of 6.5% from 2021 to 2026, reaching a value of $2.4 billion. This growth is propelled by the increasing demand for complex components that require high precision and multi-faceted machining capabilities. Emerging technologies, such as digital twin simulations and real-time analytics, are enabling manufacturers to optimize their processes, reducing waste while enhancing productivity.

In the realm of advancements, automation and robotics are becoming integral to 5-axis milling operations. The integration of AI-driven solutions is expected to enhance machine learning capabilities, facilitating predictive maintenance and reducing downtimes. A study by Frost & Sullivan emphasizes that these technologies can lead to efficiency gains of up to 30%, making them crucial for manufacturers aiming to stay competitive. The shift towards Industry 4.0 and smart manufacturing will likely usher in a new era of 5-axis milling, where interconnected systems and advanced data analytics play a pivotal role in driving precision and manufacturing efficiency.

Related Posts

-

Essential Checklist for Choosing Your Perfect 3 Axis Milling Machine

-

How to Choose the Right Milling Machine for Your Business Needs

-

How to Choose the Right Machining Center for Your Manufacturing Needs

-

How to Optimize Your Workflow with a 5 Axis Milling Machine

-

Unlocking Precision: How CNC Machines Revolutionize Manufacturing Today

-

Unlocking Precision: The Ultimate Guide to Machining Centers for Advanced Manufacturing Techniques