- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

Essential CNC Milling Tips for Beginners to Succeed?

CNC milling is an essential skill for anyone looking to master machining. As expert machinist John Smith once said, "Precision in CNC milling can turn ideas into reality." For beginners, understanding the intricacies of CNC milling is crucial.

Newcomers often face challenges when starting their CNC milling journey. The learning curve can be steep, and mistakes are part of the process. Overlooking the basics can result in costly errors. It’s essential to embrace these lessons and learn from them to enhance your skills.

Pay attention to details like tool selection and machine calibration. They can greatly impact the final outcome. Experimenting with different materials will also yield valuable lessons. Each project will highlight the importance of precision, patience, and creativity in CNC milling. Emphasizing practice and persistence will lead to future success.

Understanding the Basics of CNC Milling for Beginners

CNC milling is an essential skill for beginners in the machining world. Understanding its basics can greatly enhance productivity. Reports indicate that over 80% of CNC users find initial training challenging. Proper guidance is key to avoiding mistakes.

Beginners often struggle with programming. The coding language can seem daunting. It's easy to make errors if one isn't careful. A recent study revealed that nearly 30% of new operators faced difficulties in their first projects. Recognizing common mistakes helps. Simple errors, like wrong tool selection or incorrect feed rates, can lead to project failures. Addressing these issues early is crucial.

Precision in milling is vital. Data shows that a 0.1mm error can lead to significant quality issues in finished parts. Understanding tooling and material compatibility can help avoid these pitfalls. New users should focus on learning the basics first. Experimenting with different materials can provide insight. These hands-on experiences are invaluable. Observing where things went wrong fosters growth in skills.

Key Terminology and Concepts in CNC Milling

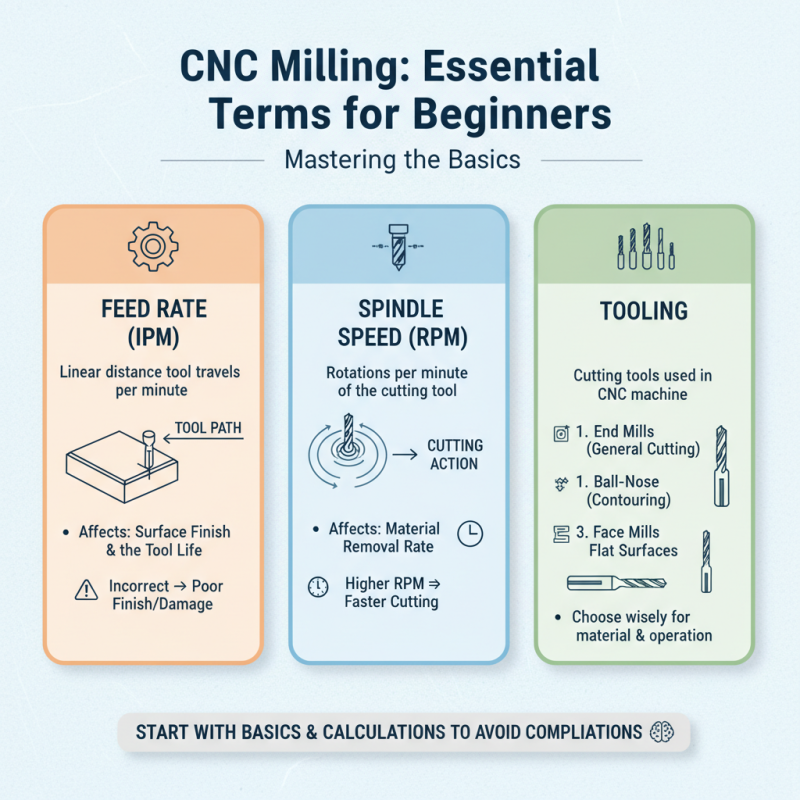

CNC milling requires a solid understanding of key terminology and concepts. Beginner machinists should familiarize themselves with essential terms. These include feed rate, spindle speed, and tooling. Each term plays a critical role in the machining process. An incorrect feed rate can lead to poor surface finish or tool damage. Spindle speed affects the material removal rate. Start with basic calculations to avoid complications.

Understanding the difference between 2D and 3D milling is vital. 2D milling addresses flat surfaces, while 3D milling shapes complex forms. Beginners often overlook machine setup. Setting up incorrectly can ruin a workpiece. Pay attention to tool alignment and zero-point references. These steps may seem minor, but they lead to better accuracy.

Learning is a process filled with mistakes. Tools might break, and parts can be wasted. This happens to everyone, even the pros. Embrace these setbacks as learning opportunities. Reflect on what went wrong. Adjust your approach for future projects. Experience will enhance your skills over time. Each lesson learned brings you closer to success in CNC milling.

Essential Tools and Equipment for Successful CNC Milling

Choosing the right tools and equipment is crucial for successful CNC milling. Start with a reliable CNC milling machine that fits your specific needs. Make sure it has a good range of features. Different machines suit different projects. It’s essential to understand the capabilities of your equipment.

Additionally, don’t overlook the importance of high-quality cutting tools. Select tools made from durable materials. This can help prevent frequent replacements. Keep in mind, the wrong cutting tool can ruin your workpiece. It's also good practice to have a variety of tools on hand for different tasks.

Here are some tips: always keep tools sharp. Dull tools can lead to mistakes and wasted material. Regular maintenance of your equipment cannot be ignored. Check for wear and tear regularly. It’s easy to forget this step, but overlooking it can result in poor milling quality. Always review your setup before starting to prevent unexpected issues.

Programming Basics: G-code and CNC Software for Beginners

Understanding G-code is crucial for CNC beginners. G-code is the language that tells the CNC machine what to do. It consists of commands that instruct the machine on movement, speed, and tool changes. For novices, mastering G-code can seem daunting. However, starting with basic commands helps build a strong foundation. Simple commands like G00 for rapid movement or G01 for linear interpolation are essential. Misunderstanding these can lead to errors in machining. Remember to double-check your commands before running any program.

CNC software plays a significant role in programming. Many options are available, but each has its learning curve. Popular features include toolpath simulation and integrated G-code generation. Utilize tutorials to overcome initial challenges with the software. Don’t be afraid to make mistakes during the learning process. Experimentation is key. You may encounter unexpected results, but these moments are valuable for growth. With persistence, proficiency in both G-code and CNC software will improve, leading to more successful projects. Stay curious and keep practicing.

Essential CNC Milling Tips for Beginners to Succeed

| Tip | Description | G-code Example | CNC Software |

|---|---|---|---|

| Understand Your Machine | Familiarize yourself with the capabilities and limitations of your CNC milling machine. | N10 G90 | Fusion 360 |

| Use Proper Tooling | Select the right tools for your material to ensure quality cuts. | N20 T1 M6 | CAMotics |

| Feed and Speed Calculation | Calculate appropriate feed rate and spindle speed for your operation. | N30 S1200 F20 | SolidWorks |

| Regular Maintenance | Perform regular maintenance to keep your machine in top working condition. | N40 M10 | Mastercam |

| Safety First | Always wear proper safety gear and ensure that all safety protocols are followed. | N50 M30 | CNC Simulator Pro |

Common Mistakes to Avoid in CNC Milling Projects

When starting with CNC milling, avoiding common mistakes can significantly impact your success. One frequent error is neglecting proper material selection. Each material behaves differently under a cutter. Using the wrong type can ruin your project. For instance, soft materials like foam or plastics require different settings than metals.

Another mistake is skipping the crucial step of creating a detailed plan. Rushing into the milling process often leads to overlooked dimensions or incorrect feeds and speeds. Without a clear blueprint, you may waste materials. Cutting tools might break, leading to frustration. Taking time to measure and prepare will enhance your precision.

Lastly, many beginners underestimate tool maintenance. Dull tools can cause poor finishes and increase wear on your machine. Regularly check and replace tools when needed. These small but crucial steps can prevent costly mistakes and lead to better outcomes in your CNC projects. Reflect on these aspects as you begin your journey.

Common Mistakes to Avoid in CNC Milling Projects

Related Posts

-

Exploring the Impact of CNC Milling on Modern Manufacturing Techniques

-

Unlocking Precision: How CNC Machines Revolutionize Manufacturing Today

-

Ultimate Guide to Best 5 Axis CNC Milling Machine Comparison for International Buyers

-

5 Reasons High Speed CNC Machining Can Boost Your Production Efficiency by 50 Percent

-

5 Best Strategies to Maximize Efficiency with 3 Axis CNC Machines

-

10 Must-Know Facts About CNC Processing to Boost Your Business Efficiency