- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

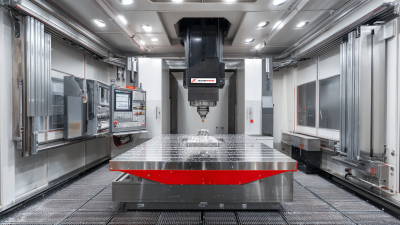

How to Choose the Right Machining Center for Your Manufacturing Needs

In today’s fast-paced manufacturing environment, selecting the right machining center is crucial for optimizing productivity and ensuring precision in production processes. With a myriad of options available, each offering distinct features and functionalities, manufacturers must consider various factors to make an informed decision that aligns with their specific operational needs.

From evaluating the machining center's capabilities, such as 3-axis versus 5-axis machining, to assessing its compatibility with current systems and budget constraints, the decision-making process can be daunting.

This guide aims to provide valuable insights and practical tips on how to choose a machining center that not only meets your manufacturing requirements but also enhances overall efficiency and output. Whether you are a seasoned professional or new to the industry, understanding the nuances of different machining centers will empower you to make a choice that drives success for your manufacturing operations.

Understanding Your Manufacturing Requirements for Machining Centers

Choosing the right machining center is crucial for meeting specific manufacturing requirements, especially as industries grow increasingly competitive. Understanding the intricacies of your production needs is the foundation for selecting an appropriate machining center that optimizes efficiency and precision. For instance, a report by the Association for Manufacturing Technology indicates that effective CNC machining can enhance productivity by up to 50% in various applications, illustrating the significant impact of tailored machinery on manufacturing output.

The surge in demand for drone components has drawn attention to advanced CNC machining capabilities. Data from industry research reveals that the drone market is expected to grow at a compound annual growth rate of over 20%, driving the need for precise and specialized manufacturing processes. As companies adapt to meet this demand, upgrading machining centers to process materials like titanium becomes essential.

Titanium's lightweight and durable properties make it ideal for drone applications, and precise machining is necessary to achieve the high tolerances required in aerospace industries. By understanding these manufacturing requirements and integrating appropriate technologies, businesses can remain competitive in the rapidly evolving market landscape.

Key Features to Look for in a Machining Center

When selecting a machining center, understanding the key features is pivotal to meeting your manufacturing needs effectively. One of the primary aspects to consider is the machine's rigidity and stability. According to a recent study by the National Tooling and Machining Association (NTMA), nearly 30% of machining errors stem from inadequate rigidity, which can lead to significant cost overruns and production delays.

Therefore, investing in a machining center with a robust frame and high-quality materials is essential for maintaining precision and prolonging tool life.

Additionally, the type of control system plays a critical role in enhancing productivity. The use of advanced CNC systems can improve operational efficiency by as much as 20% by streamlining machining processes and offering real-time data analytics. Furthermore, a machining center with multi-axis capabilities enables more complex geometries to be machined in a single setup, thus reducing cycle time and minimizing the risk of errors that may occur in multiple setups.

As manufacturers aim for more automated and flexible solutions, prioritizing these key features will ensure optimal performance and a better return on investment.

Evaluating the Technology and Controls of Machining Equipment

When selecting a machining center, understanding the technology and controls integrated into the equipment is crucial for meeting your manufacturing demands. Advanced machining centers come with a variety of technological enhancements, such as multi-axis capabilities and automation features. These elements not only improve precision but also increase production efficiency. It is essential to assess how well the technology aligns with your specific applications, whether you require high-speed cutting for intricate components or heavy-duty operations for larger parts.

In addition to technology, the control systems of machining equipment play a significant role in their overall functionality. Modern machining centers often feature intuitive interfaces and powerful software that streamline programming and operational control. Evaluating the user-friendliness of the control system is vital; a complex interface might hinder productivity, while a straightforward system can enhance operator efficiency. Furthermore, ensure that the controls offer versatile programming options, such as support for G-code and CAD/CAM integration, to adapt to your evolving manufacturing needs. Careful consideration of these aspects will empower you to choose a machining center that not only meets your immediate requirements but also positions your business for future growth.

Comparing Different Types of Machining Centers for Your Application

When selecting a machining center, it's essential to compare different types to find the best fit for your specific manufacturing application. The three primary categories include vertical machining centers (VMC), horizontal machining centers (HMC), and multitasking machining centers. According to a report by MarketsandMarkets, the global CNC machining center market is expected to reach $118 billion by 2026, growing at a CAGR of 5.5% from 2021. This growth illustrates the increasing demand for precise and efficient manufacturing solutions.

Vertical machining centers are favored for their versatility and compact footprint, making them ideal for smaller shops focused on detail-oriented components. On the other hand, horizontal machining centers excel in larger production runs and heavy part machining thanks to their stability and automated loading capabilities. The 2021 Techspex Industry Report notes that HMCs can increase productivity by up to 40% in high-volume operations. Lastly, multitasking centers combine multiple processes in one setup, significantly reducing cycle times and enhancing operational efficiency, a crucial advantage as industries continue to lean towards lean manufacturing practices. Each type has unique strengths, making the correct choice contingent upon your specific production requirements and goals.

Comparative Analysis of Different Types of Machining Centers

Budgeting for Your Machining Center Investment and Maintenance Costs

When considering an investment in a machining center, budgeting plays a crucial role in determining the overall feasibility of the purchase. Initially, it's essential to understand the upfront costs, which include not only the price of the machine itself but also expenses related to installation, training, and any necessary accessories. Ensure you research various models and brands to find one that fits your operational needs while staying within your financial limits. A detailed cost analysis will help in identifying the best options that provide value for money.

Related Posts

-

Understanding the Features of the Best CNC Machining Center for Your Business

-

How to Choose the Right Milling Machine for Your Business Needs

-

Challenges Faced by Industries When Using CNC Machines

-

The Ultimate Guide to High Precision Machining for Global Buyers in 2023

-

Unlocking the Technical Specifications of the Best Vertical CNC Machine for Peak Performance

-

Essential Checklist for Choosing Your Perfect 3 Axis Milling Machine