- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

Top 5 Benefits of High Precision Machining for Modern Manufacturing

In the realm of modern manufacturing, the significance of high precision machining cannot be overstated. As industries strive for unparalleled accuracy and efficiency, experts like Dr. Emily Carter, a leading authority in advanced manufacturing technologies, emphasize the game-changing capabilities of this technique. Dr. Carter once stated, "High precision machining is not just about functionality; it's about transforming the way we think about production and design." This transformative approach has paved the way for numerous benefits that enhance operational performance and product quality.

High precision machining offers manufacturers a multitude of advantages, which are essential in today’s competitive landscape. From reducing production costs through minimized material waste to ensuring tighter tolerances that result in superior product quality, the impact of this technology is profound. As we explore the top five benefits of high precision machining, it becomes clear that investing in this method is not merely an option but a necessity for businesses aiming to remain at the forefront of their industries. Embracing high precision machining allows manufacturers to leverage innovation, ultimately reshaping the future of production processes and product development.

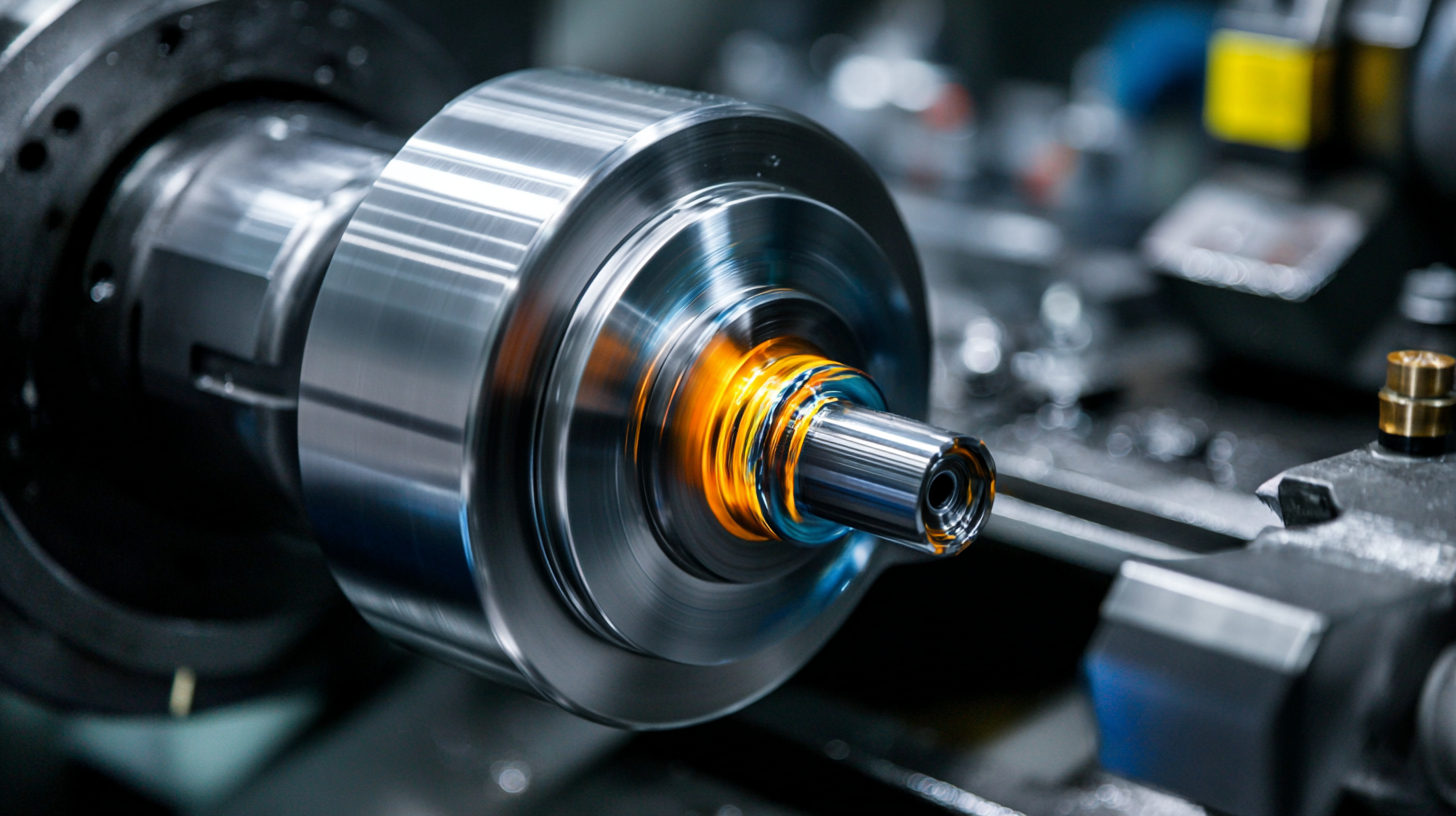

Enhancing Product Quality Through High Precision Machining

High precision machining plays a pivotal role in enhancing product quality in modern manufacturing. With the global CNC machine market projected to grow from $101.22 billion in 2025 to $195.59 billion by 2032, registering a compound annual growth rate (CAGR) of 9.9%, the significance of high precision machining in meeting manufacturing demands cannot be overstated. This growth indicates an increasing reliance on advanced machining techniques to produce components with tighter tolerances and improved reliability, ultimately leading to better product performance.

As the industry evolves, innovations such as high-precision turning and milling are becoming essential. The precision turned product manufacturing market alone is expected to reach approximately $196.11 billion by 2034. Such data reflects an industry-wide trend toward precision, as manufacturers seek to reduce waste and enhance efficiency—all while improving the overall quality of their products.

The integration of high-precision confocal sensors, projected to reach $468.7 million by 2035, also highlights the technological advancements that support quality assurance in machining processes. These developments collectively contribute to a manufacturing environment where high-quality output is not just a goal but a standard expectation.

Reducing Waste and Material Costs with Accurate Machining Techniques

High precision machining plays a crucial role in modern manufacturing by significantly reducing waste and lowering material costs. By utilizing advanced machining techniques, manufacturers can achieve tighter tolerances and improved surface finishes, which in turn minimizes the excess material removed during production processes. This precision not only enhances product quality but also leads to substantial savings on raw materials, ultimately making the manufacturing process more economical.

Tips for manufacturers looking to implement high precision machining include investing in state-of-the-art machinery and tooling. Ensuring that your equipment is up-to-date can greatly enhance accuracy and efficiency. Additionally, regular training for operators on the latest techniques and technologies can further improve machining processes, allowing them to capitalize on precision capabilities fully.

Another strategy is to integrate computer-aided design (CAD) and computer-aided manufacturing (CAM) systems to streamline workflows. These systems help in optimizing designs for manufacturability, ensuring that every piece produced meets strict quality benchmarks while minimizing scrap. By focusing on precision from the design phase, manufacturers can maximize operational efficiency and significantly reduce material wastage.

Top 5 Benefits of High Precision Machining for Modern Manufacturing

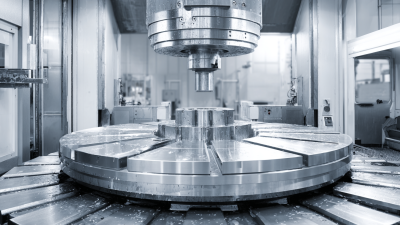

Boosting Production Efficiency in Modern Manufacturing Environments

High precision machining has become a cornerstone of modern manufacturing, particularly in enhancing production efficiency. By utilizing advanced technologies and detailed processes, manufacturers can achieve exceptionally tight tolerances and superior surface finishes. This precision not only reduces the margin for error but also minimizes waste, leading to a more streamlined production line. As a result, companies can respond more quickly to market demands, ultimately boosting their competitiveness.

Tips for improving production efficiency include investing in high-quality tools and equipment that are specifically designed for precision machining. Regular maintenance of machinery is crucial to ensure optimal performance and longevity. Additionally, incorporating automation and advanced software solutions can facilitate real-time monitoring of production processes, allowing for immediate adjustments that can prevent costly delays.

Another effective strategy is to provide ongoing training for employees, ensuring they are well-versed in the latest machining techniques and technologies. Engaging workers in the continuous improvement process fosters a culture of innovation while also enhancing overall productivity. By focusing on these areas, manufacturers can reap the benefits of high precision machining and drive efficiency throughout their operations.

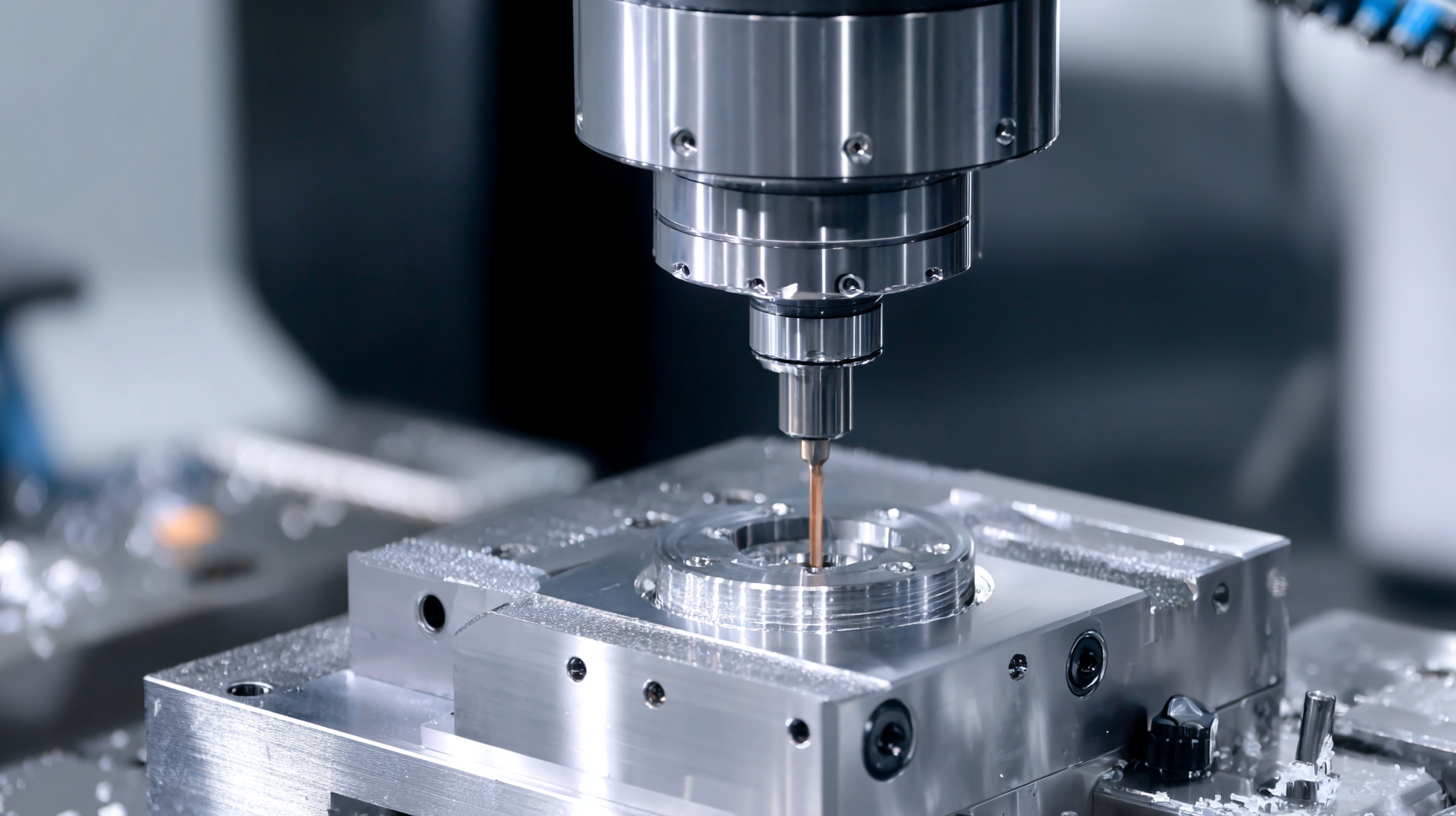

Facilitating Customization and Design Flexibility via Precision Machining

High precision machining has revolutionized the manufacturing landscape by offering

unparalleled customization and design flexibility. Manufacturers can utilize advanced CNC machines to produce intricate components

that meet specific client requirements, accommodating a wide range of applications across industries.

This level of precision not only enhances the aesthetic appeal of products but also optimizes functionality, allowing designs to be adapted quickly as market demands evolve.

Furthermore, precision machining facilitates the development of complex geometries that traditional

manufacturing methods struggle to achieve. This capability enables engineers and designers to push the boundaries of innovation,

bringing novel ideas to life without compromise. The ability to easily modify designs also shortens lead times, allowing businesses to

respond swiftly to changes and demands in the marketplace. By embracing high precision machining, companies are not only streamlining

their production processes but also enhancing their competitiveness in an increasingly dynamic environment.

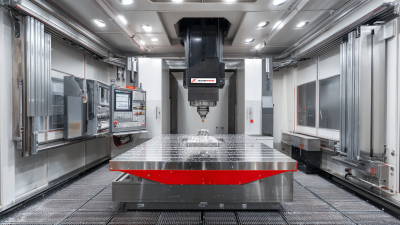

Improving Supply Chain Reliability with High Precision Manufacturing Standards

High precision machining plays a pivotal role in enhancing supply chain reliability in modern manufacturing. By adhering to stringent manufacturing standards, companies can produce components with exceptional accuracy and consistency. This reliability substantially minimizes discrepancies in product quality, leading to fewer defects and reducing the need for rework. As a result, manufacturers can maintain the integrity of their supply chains, ensuring that parts are delivered on time and meet the exact specifications required for assembly.

Moreover, high precision machining fosters stronger relationships among supply chain partners. With reliable manufacturing processes, companies can confidently forecast production schedules and inventory needs. This transparency not only streamlines operations but also builds trust between suppliers and manufacturers. When all parties involved can count on precise and dependable component delivery, it bolsters overall efficiency, reduces lead times, and ultimately contributes to a more robust manufacturing ecosystem.

Top 5 Benefits of High Precision Machining for Modern Manufacturing

| Benefit | Description | Impact on Supply Chain | Example Industry |

|---|---|---|---|

| Increased Accuracy | High precision machining reduces tolerances, leading to more accurate parts. | Enhances product reliability, reducing the number of defective items in the supply chain. | Aerospace |

| Cost Efficiency | Reduces waste and machining time, lowering overall production costs. | Allows for better budgeting and forecasting in supply chain management. | Automotive |

| Enhanced Flexibility | High precision machines can be quickly adjusted for different tasks. | Facilitates rapid response to market changes, improving supply chain agility. | Electronics |

| Better Material Utilization | Minimizes waste materials through precise cutting and shaping. | Contributes to sustainable practices and reduces supply chain costs. | Medical Devices |

| Quality Control | Allows for stringent quality checks, ensuring higher standards. | Reduces risks of recalls and enhances trust in supply chain partners. | Defense |

Related Posts

-

Ultimate Checklist for Selecting the Best 5 Axis Machining Services

-

The Ultimate Guide to High Precision Machining for Global Buyers in 2023

-

Understanding the Features of the Best CNC Machining Center for Your Business

-

Ultimate Guide to Best 5 Axis CNC Milling Machine Comparison for International Buyers

-

Understanding Industry Production Standards for Optimal High Speed Machining Performance

-

Discover How Best Precision Machining from China Leads Global Manufacturing Excellence